THE TESTS

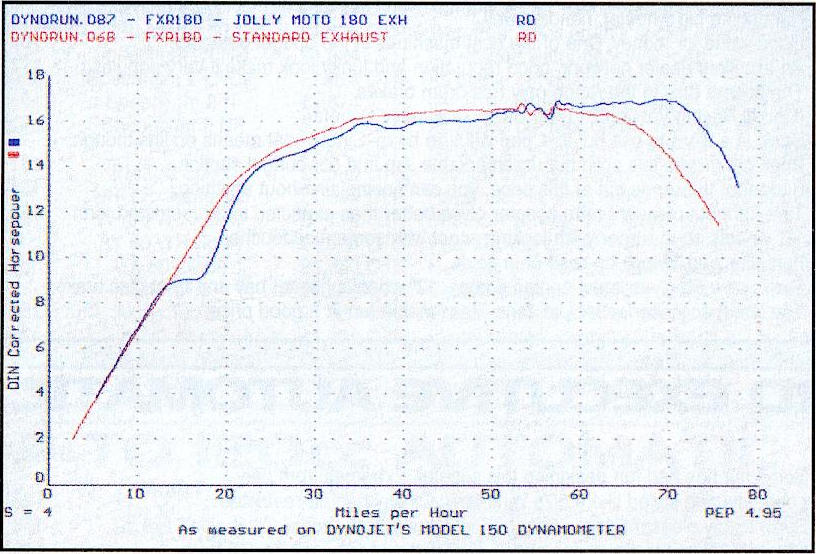

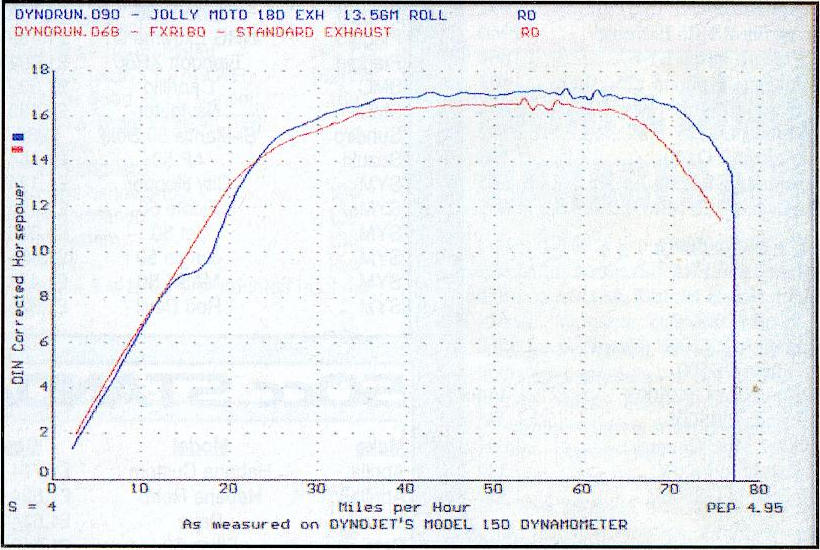

The you may have noticed that the standard power curve on the dyno graphs here - which show a curve o f little m. ore than 16 hp- is. "not quite as healthy as the 17.2hp standard exhaust "curve of the previous tests. The problem stems from the fact that the dyno is merely a comparitor, rather than an absolute measuring device like a stopwatch or a ruler. The power loss is due to a change in weather, with this second test being conducted within an extremely low barometric pressure. Air pressure is important to a petrol engine because the oxygen in the air is one of the main things that it runs on. When the air density is low, the engine gets less oxygen each time it takes a cylinder full of gas, so it makes less power. If you want to test this theory, try riding your scooter over the Alps because the low air density up high mountains will make your engine feel totally gutless. This same phenomenon can be noticed at ground level simply from barometric changes. The software for the Dynojet Dyno tries to compensate for weather changes by using Correction Factors to modify the curve. This is done in order to try and maintain a more balanced comparison, but these tend to be conservative and can't be relied up on to ensure comparable graphs when there have. been some changes in air pressure. To that end, you should not compare the specific power out puts ( in terms of to the graphs shown in issue 175. Instead, just compare each pipe the standard exhaust and note the amount of gain or loss. This gain or loss should be similar no matter what to the weather conditions are, or how well the standard exhaust behaves.

|

The actual testing was carried out as before, with each exhaust run several times from 20 mph up to almost 80 mph until we had a stable power curve. Then the machine was accelerated from a standstill to get the blue curves shown here. In every case the standard exhaust is displayed in red. The point of this article is to show exactly what performance to expect from any of these exhausts if they are bolted onto a standard Runner /Dragster 180. These results are largely irrelevant once you get involved in tuning and fitting kits, because other higher revving exhausts may then be better suited to the engine's characteristics.

WHAT WE TESTED

As far as the hoped for systems went, our quest was largely fruitless. Kegra Racing did not manage to make us one of their pipes in time (which bolts to the standard downpipe) though Graham swears it makes more power than standard. PM Tuning declined to submit a brand new PM55 Mk2 because they are currently working on a new model, which should be shorter, more nicely styled, and make even more power. In the mean time, Paul is reducing the price of the PM55 Mk2 to make room for the new system to sell at £220. As far as the Sito Plus and Gianelli Freeway are concerned, again we couldn't get a correctly produced sample to test in time. What that leaves us with is the new Leo Vinci Touring exhaust (which should sell head to head with the Gianelli and the Sito Plus), SIP's new stainless steel downpipe, and a brand new 180-specific expansion chamber from Italian tuners Jolly Moto.

|

CONCLUSION

The overall result is that with the Jolly Moto we now have a third pipe (along with the PM 55 Mk2 and Stoffi ASP2) that produces a worthwhile advantage on the Runner 180, and one that is also fairly quiet. Even so, the ASp2 remains the best we have tested for power output, particularly since you don't need to change the transmission rollers to get the best out of it, as you do with the Jolly Moto.

Sticky

Thanks to: Taffspeed Racing for the Dyno Testing, and all those who supplied exhausts to test.

NEXT MONTH: We dyno three

Lambretta exhaust systems for cast iron barrels.

Contact Details:

Taffspeed: Tel 01633 840450 www.taffspeed.co.uk

Jolly Moto: Tel/Fax 0049 66571586 or

e-mail: hartungheiko@gmx.de

SIP: Tel 0049 8191942303 www.sip-scootershop.de

PM Tuning: Tel 01524 823900 www.pmtuning.co.uk

V.E. Spares: www.ve-uk.com

Stoffi's Garage: Tel 0043 7752 88707 www.stoffis.com

|